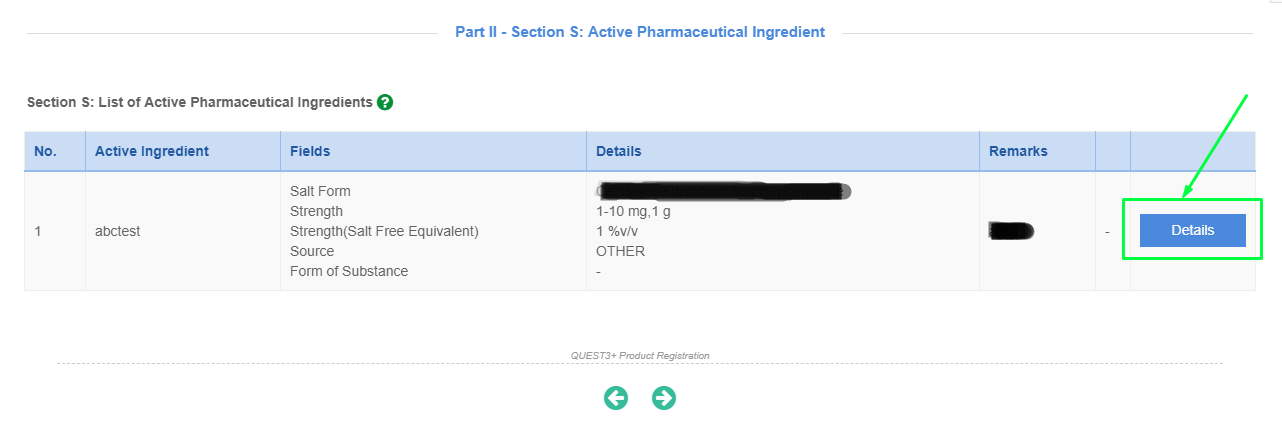

Part II, Section S : Active Pharmaceutical Ingredient (API) Information Submission

Please click "Details" button to open Section S for each API.

Please refer:

- DRGD Page 211 – 226

- WHO TRS 814 (1991) Annex 3: Guidelines for assuring the quality of pharmaceutical and biological products prepared by recombinant DNA technology

- WHO TRS 822 (1991) Annex 3: Guidelines for assuring the quality of monoclonal antibodies for use in humans

- WHO TRS 878 (1998) Annex 1: Requirements for the use of animal cells as in vitro substrates for the production of biologicals

- CHMP/BWP/157653/07: Production and quality control of monoclonal antibodies and related substances

- CPMP/BWP/328/99: Development pharmaceutics for biotechnological and biological products (Annex to note for guidance on development pharmaceutics)

- CHMP/BWP/157653/2007: Guideline on development, production, characterisation and specifications for monoclonal antibodies and related products

- ICH Guidelines related to Biotechnological/ Biological products

The Quality Overall Summary (QOS) is a summary that follows the scope and the outline of the Body of Data in Module 3. The QOS should not include information, data or justification that was not already included in Module 3 or in other parts of the CTD. The QOS should include sufficient information from each section to provide the Quality reviewer with an overview of Module 3. The QOS should also emphasize critical key parameters of the product and provide, for instance, justification in cases where guidelines were not followed. The QOS should include a discussion of key issues that integrates information from sections in the Quality Module and supporting information from other Modules (e.g. qualification of impurities via toxicological studies discussed under the CTD-S module), including cross-referencing to volume and page number in other Modules. This QOS normally should not exceed 40 pages of text, excluding tables and figures.

To attach the Print Form (Section S – Drug Substance) once all the documents are completed prior to submission

- International non proprietary names / INN

- Chemical names

- Synonyms

- CAS No

- Structural formula (relative and absolute chemistry)

- Molecular formula

- Molecular weight

- Molecular weight (base)

Description of physicochemical and biological properties.

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Name and full address including the city and country of the manufacturer(s)

- List of processes/ activities involved for all the listed manufacturer facilities

- Attach GMP certificate in S9

Manufacturers involved in each production steps, including intermediate manufacturer, milling and quality control testing sites.

* GMP certificate is required for all manufacturer involved in API manufacturing process, including intermediate manufacturing and milling sites

- A flow chart should show the steps in production and in a complete list of the in-process controls and tests performed on the product at each step.

Reference:

- ICH Q5A (R1): Viral safety evaluation of biotechnology products derived from cell lines of human or animal origin

- ICH Q5B: Analysis of the expression contruct in cells used fro production of r-DNA derived protein products

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

A flow chart should show the steps in production and in a complete list of the in-process controls and tests performed on the product at each step.

Reference:

- ICH Q5A (R1): Viral safety evaluation of biotechnology products derived from cell lines of human or animal origin

- ICH Q5B: Analysis of the expression contruct in cells used fro production of r-DNA derived protein products

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

Please provide:

- List of all materials (raw material, culture media, buffers, resins for peptide synthesis, chemicals, columns etc.) and their tests and specifications, or reference to pharmacopoeia. Information on: source, manufacture and characterisation.

- Include complete history and characterization/ characteristics of each species, strain, cell banking systems - Master Cell bank (MCB) and Working Cell Bank (WCB), cell/ seed lot system, seed development, cell substrate system, animal sources (including fertilized avian eggs), virus source or cellular sources.

- Summaries of viral safety information for biologically -sourced materials should be provided

- Indicate where each material is used in the process

- Characterisation: control tests, methods and acceptance criteria of these materials

- If conjugate of adjuvant is used, justification is warranted

Reference:

- ICH Q5A (R1): Viral safety evaluation of biotechnology products derived from cell lines of human or animal origin

- ICH Q5B: Analysis of the expression contruct in cells used fro production of r-DNA derived protein products

- ICH Q5C: Stability testing of biotechniologica/ biological products.

- ICH Q5D: Derivation and characterisation of cell subtrates used for production of biotechnological/ biological products.

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- WHO TRS 878 (1998) Annex 1: Requirements for the use of animal cells as in vitro substrates for the production of biologicals

- To describe all process controls conducted during production and its intermediates as well as release control programs carried out in the intermediates

- Critical steps – tests and acceptance criteria, with justification

- Must include experimental data, performed at critical steps of the manufacturing process to ensure that the process is controlled

- Intermediates – specifications and analytical procedure, if any, for intermediates isolated during the process

Reference:

- ICH Q5A (R1): Viral safety evaluation of biotechnology products derived from cell lines of human or animal origin

- ICH Q5D: Derivation and characterisation of cell subtrates used for production of biotechnological/ biological products.

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Process validation and/or evaluation studies for aseptic purification

- The process validation performed must be able to demonstrate process consistency (including viral validation) and to determine critical process parameters

- To provide a list of the processes validated (e.g. production process(es), cleaning process(es), sterilization/depyrogenation processes, and simulations such as fermentation, lyophilization and media fills); a brief description of each of the validation studies including the selection of worst case situations to cover all situations, the current status of validation, and the re-validation frequency. This could be provided in a table.

- For media fills, give the frequency of media fills, media used, incubation conditions, the fill sizes/volumes/# vials/shift simulation, the number of times per year for each of the filling staff, and number of runs.

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Description and discussion of significant changes made to the manufacturing process and/or manufacturing site of the drug substance used in producing non-clinical, clinical, scale-up, pilot and if available, production scale batches. This should include the conjugation process as well.

- The development history of the manufacturing process as described in S 2.2, should be provided

- The history of changes in development program can be presented in a table form, highlighting changes between the lots used in the nonclinical and clinical development and commercial production. E.g. of changes include process or critical equipment, with the reason for change explained.

- The significance of change should be assessed by evaluating its potential to impact the quality of the drug substance (and/or intermediate, if appropriate). For manufacturing changes that are considered significant, data from comparative analytical testing on relevant drug substance. A discussion of the data including a justification for selection of the test and assessment of results, should be included.

- Testing used to assess the impact of manufacturing changes on the drug substance(s) and the corresponding drug product(s) may also include non-clinical and clinical studies in other modules of the submission should be included.

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

Details on primary, secondary and higher-order structure and information on biological activity, purity and immunochemical properties (when relevant).

- Confirmation of structure based on routine QC release structural analyses such as:

- Molecular size by size exclusion HPLC

- Proton NMR to determine O-acetyl content

- Identity testing

- Specific testing like multiple angle laser ling scattering (MALLS) may also be done

- Data and tests done should be able to provide proper characterisation of the vaccine structure

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

Reference:

- ICH Q5C: Stability testing of biotechniologica/ biological products.

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Detailed specification, tests and acceptance criteria

- Compendial specification or appropriate information from the manufacturer

- Data to ensure that impurities and within the specification range previously justified

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- The analytical procedures used for testing of drug substance should be provided in sufficient detail to enable reproducible testing by another laboratory

- Compendial methods or appropriate information from the manufacturer

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Analytical validation information, including experimental data for the analytical procedures used for testing the drug substance

- Typical validation characteristics to be considered:

- selectivity

- precision (repeatability, intermediate precision and reproducibility)

- accuracy

- linearity

- range

- limit of quantitation

- limit of detection

- robustness

- system suitability

- Non-compendial methods should be provided in full

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

Description of batches and results of the analysis to establish the specification

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

Description of batches and results of the analysis to establish the specification

S4.4.1 (i) API Manufacturer (2 Batches)

S4.4.1 (ii) Product Manufacturer (2 Batches)

- Information on the quality of the reference standards or reference materials used for testing of the drug substance

- Compendial reference standard should be identified, with reference.

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Information on the quality of the reference standards or reference materials used for testing of the drug substance

- Compendial reference standard should be identified, with reference.

Reference:

- ICH Q6B: Specifications: Test procedures and acceptance criteria for biotechnological/ biological products

- Descriptions of the container closure systems, including:

- the identity of materials of construction of each primary packaging component

- specifications including description and identification (with critical dimension with drawings where appropriate)

- non compendial methods (with validations) should be included where appropriate

- Non-functional secondary packaging components (e.g. those that do not provide additional protection nor serve to deliver the product) – only a brief description should be provided

- Functional secondary packaging components – additional information should be provided

- Suitability should be discussed with respect to e.g. choice of materials, protection from moisture and light, compatibility of the materials of construction with the drug substance, including sorption to container and leaching, and/or safety of materials of construction

- For container closure components qualified within the definition of a medical device (e.g. inhaler, auto-injector, nasal spray), information on submission of dossier at the Medical Device Bureau, MOH Malaysia should be provided.

- Stability summary and conclusion (Stability report):

- the types of studies conducted, protocols used and the results of the studies should be summarized.

- The summary should include results, e.g. from forced degradation studies and stress conditions, as well as conclusions with respect to storage conditions and retest date or shelf-life, as appropriate

- Post-approval Stability Protocol and Stability Commitment should be provided (if applicable)

- Stability Data:

- narrative information on the analytical procedures used to generate the data and validation of these procedures (with specifications and rationale for choice of tests for determining stability)

- Identification of the dates of manufacture of the lots, the lot numbers, the vial and dose size, and the scale of production;

- Results of quantitative assays must be expressed as a numerical value with the appropriate limits and not as “pass” or “fail”.

- For each DS bulk/intermediate that is stored for significant periods of time (usually >30 days) before subsequent processing steps, formulation or filling, provide the expiry date at the approved storage temperatures. Give the QC tests, SOP number, and specifications that were selected for following stability of each intermediate with justification for the choices. The stability study schedule and frequency of each test should be given. Provide a list of the intermediate lot numbers on test, batch size, scale of production, storage container and volume, and dates of manufacture. Justification of the choice of these intermediate lots is requested. The stability data should be real-time real condition data.

- A table should be prepared for each lot giving the results of tests (numerical values) and specifications with discussion of any out-of-specification result and justification for accepting the result in support of the stability.

- Conclusions on stability and the claimed shelf life of intermediates should be stated.

Reference:

- ICH Q5C: Stability Testing of Biotechnological/Biological Products